– Samantha Paul, marketing specialist

Rachel and her Pomeranian named Cash.

Based in Williams Lake, British Columbia, Rachel Brink is surrounded daily by vast mountains and forests and she wouldn’t want it any other way. “It is a different lifestyle,” she says of her career in the forest industry. “It’s not regular office hours, but the views make up for it.”

Rachel’s grandfather started a truck logging company back in the early 1980s. Her father, Randy and brother, Justin built up the business from there. 37 years later, Small Pine Logging is still going strong. “At one point we had almost all family working,” says Rachel. “My sister, her ex-husband, my brother, my dad, my brother’s father-in-law, and my two cousins,” she reminisces. “My sister and our girlfriend worked with us at one point as well. We were processing, decking and road building, the three of us working together. It was pretty cool.”

“My sister is one of the best operators I have ever seen,” says Rachel. “She showed me the methods of skidding. There’s a method for each job; when and where to do what – always planning. Riding along with a skilled operator is how I learn best. I’ve been lucky to have been around some of the best. A lot comes into play while running equipment. Steep ground, the weight of the machine, the wood you’re handling, weather and season even. You have to be conscious of your surroundings.”

The 850/568 processor that Rachel operates for Small Pine Logging.

After being trained by her sister on the skidder, her father gave her a shot at running the processor. “He showed me how to do a couple of things and said, ‘You’ll figure it out.’ And I guess I did,” she laughs. Going from a skidder to a processor can be quite the learning curve with added technical challenges. “If you have run an excavator before, there are similar controls, so it is a lot easier to jump into a processor and know what you’re doing.” At age 34, Rachel has been operating for thirteen years, including the last nine years on a processor. “Every year, I think about getting a different job. But I keep coming back.”

Small Pine Logging received its first 850 processor equipped with the Tigercat 568 harvesting head in August of last year. The machine was purchased through Tigercat Dealer Inland. “Inland has been an enormous help,” she says. “Tyler Povelofskie is my favourite mechanic. He likes things fixed right not just halfway, and that is something I respect. He has a great work ethic, is easy to work with, and is always there when needed.”

Learning curve

Along with Inland, local Tigercat product support representative, Jochen Reiter, delivered the machine and assisted with the carrier and head set-up. Rachel was operating a different brand processor before getting into the Tigercat. “I am very particular in how I want it to run. Jochen was a massive help when we were first setting up the machine. He guided me through the operator control system, and now it is super easy for me. He has come out multiple times to help me when I am stuck. One night I had a problem, and I woke up to fourteen messages from him explaining how to fix the issue. Every detailed step. He is amazing.”

MY DAD IS ECSTATIC THAT I AM AN OPERATOR, HE IS SO PROUD.

Rachel says that there have been very few times in her life when she has been truly happy with her achievements. “But I am happy with what I can do with this machine. It has more power than what I am used to. It’s unreal actually. It is an amazing machine with a lot of little details you appreciate as an operator.”

Rachel with her father, Randy and brother, Justin.

“She got used to our 850/568 very quickly. The second day she cut 700 cubic metres [approximately 585 tons],” Jochen explains. “The machine is now producing 900 cubic metres [approximately 750 tons] – around thirteen to fourteen truckloads per day, which is pretty impressive,” he adds. “They are processing logs over 32 inches [80 cm] – some of the biggest logs I have seen go through the 568.”

Impressed with how logging equipment has improved over the years, Rachel confirms, “You get used to what you have been running. You don’t know what you’re missing until you get into a new machine.”

Motivation

Operating the same machine each day can become a bit monotonous. When asked how she stays motivated, Rachel explains, “I compete with myself and nobody else. You have to think about what you’re doing every second. Having a strategy in your mind to stay fast and productive is key.”

Rachel’s father is happily retired, fishing and golfing instead of logging. When the new 850 arrived, her father came out to the bush to check it out – a fond memory for Rachel. It isn’t very often her dad, brother and she are out on the job together. “My dad’s too busy living life now,” she says. “My dad is ecstatic that I am an operator. He is so proud. On the other hand, my mom would probably prefer I become a nurse and pop out a couple of babies like my sister,” laughs Rachel.

Thick skin

Rachel isn’t sure why more women don’t pursue a career as a machine operator. “I guess you have to have a bit of a thick skin to work in the bush,” answers Rachel. “It may be intimidating if you don’t already know someone in the business. The money is good, but it is a different lifestyle choice.”

“Women do make great operators. And more women need to give it a try,” she states. “There is a finesse required for operating, and women have that.” Whether male or female, you have to have a good work ethic. Rachel wouldn’t say she is competitive but she has the drive to be the best she can be every day. “No one is watching over you every minute. You have to have the drive to keep setting new goals.”

“We have some old-timers in our crew, so we had to look at getting some younger operators with a good work ethic, which can be hard to find. We have three guys in their early twenties working for us now. They are all working out very well,” she says. “The stories and jokes over the radio are hilarious. Everyone is constantly joking around.”

EVERY YEAR, I THINK ABOUT GETTING A DIFFERENT JOB.

BUT I KEEP COMING BACK!

What’s important

With the current pandemic, now more than ever, people realize the true importance of family. Rachel’s work ethic is a product of her upbringing and the role models around her. “My mom, my dad, my brother, my sister – I am surrounded by great, hardworking people with big hearts.”

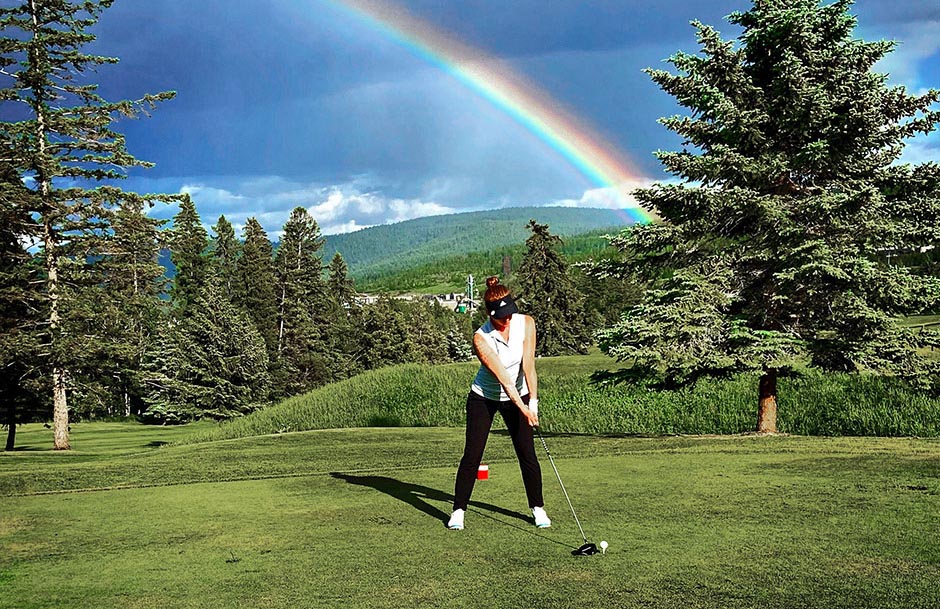

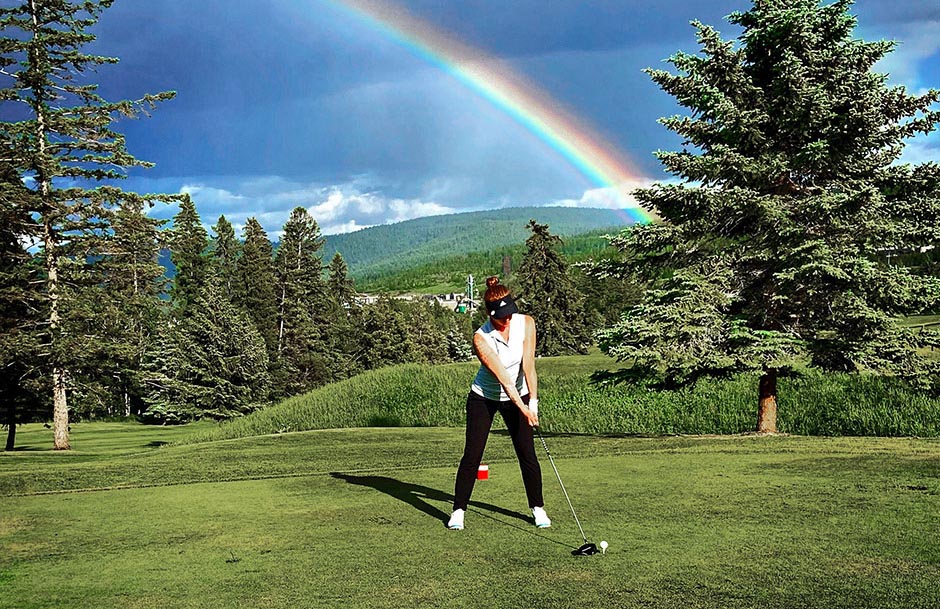

Rachel trying to stay out of the trees.

When Rachel isn’t processing, she is camping or golfing with family and friends. She has learned patience through her golf game, improving her skills over the years. “I tossed a couple of clubs when I first started,” she laughs. “But I don’t do that anymore.”