– Glen Marley, district manager, Australasia and Southeast Asia

The Wik Timber project recently purchased two Tigercat machines for its logging operations south of the Embley River, on the Western Cape York Peninsula. They were put to work clearing land for Rio Tinto Aluminium, to allow the mining giant access to the abundant supply of Bauxite. The rock, a primary ore of aluminum, is extracted and exported to the lucrative Asian market from this very remote northern region of Australia. Wik Timber Holdings is an Indigenous business and the timber harvesting, wood-chipping and seed collection operations will provide jobs for local Aboriginal people resident in and around Aurukun and Napranum.

Wik Projects strategic initiatives and operations manager is Jacky Castelain. His senior management team includes his daughter Gina Castelain, the managing director of Wik Timber and Mark Annandale, research manager for Tropical Forests and People Research Centre at the University of the Sunshine Coast in Queensland. Several other highly motivated and dynamic people are working on this project and based in and around Weipa. Jacky is very hands-on with the operations.

The Wik and Wik Waya people have a rich history associated with logging and milling going back well over 100 years.

With very high levels of social disadvantage and few employment opportunities, Aurukun has been recently described as a community in crisis. Gina, overseeing a group of Wik and Wik Waya owned businesses aiming to generate jobs, income and independence for the Wik people estimates, “Probably 98 percent of the population in the region is on welfare or part of the welfare dependency cycle. We want to create real jobs – people in meaningful jobs and on their traditional country. It’s heartbreaking and a real waste to see the timber pushed up and burned. And we can’t continue to keep wasting this valuable timber resource.”

Over the past five decades of bauxite mining on Cape York, mine site preparation has involved using bulldozers pulling chains to clear the forest, followed by windrowing and burning to waste. Two key areas of Indigenous community concern are the current pre-mining management practices and the outcomes of post-mining landscape rehabilitation efforts.

Currently, bauxite mining operations clear and burn an average of approximately 1 500 hectares (3,700 acres) of native forest per year, representing approximately 210 000 tonnes (230,000 tons) of forest biomass. Rio Tinto’s Amrun project – extending mining activities south of the Embley River, between Weipa and Aurukun – is estimated to require additional clearing of around 28 000 hectares (70,000 acres) of forest, representing around 4,2 million tonnes (4.6 million tons) of forest biomass. “Substantial quantities of greenhouse gases are being emitted, says Gina. “Bauxite mining is expected to continue for at least another 50 years and the continued burning of forest products would be a major lost commercial business and employment opportunity for the region’s Indigenous communities and a significant ongoing source of greenhouse gas pollution.”

Jacky Castelain is impressed with the build quality of the machines.

Gina, along with other Indigenous community leaders, knew they were not making use out of the high value timber – Darwin Stringybark, Cooktown Ironwood and Melville Island Bloodwood – that was being disposed of. Sound harvesting with a diverse range of products, including saw logs, peeler logs and biomass chips, along with value-adding operations seemed to be the logical long-term answer. Demand for the various products is expected to come from Chinese, Vietnamese and domestic sawmillers and manufacturers of timber-based products. In addition, power transmission poles will be marketed to electricity distributors, Rio Tinto Aluminium will require railway sleepers, and Rio Tinto Aluminium and others will demand chips for mine rehabilitation.

The Wik and Wik Waya people have a rich history associated with logging, milling and home building in this region going back well over 100 years. The Aurukun and Napranum communities both operated sawmills to supply products such as home building materials, local farm fencing and railway sleepers up until the Napranum mill finally stopped production in 2012.

The new 610E skidder pulling a hardwood drag.

A long tradition of sustainable and responsible forest, land, environmental, historical, and cultural management in this region guides the vitally important goal of developing a commercially viable and sustainable business plan for forest harvesting, as well as fire management and mine rehabilitation operations. When at full scale, the business will produce up to 125 000 tonnes (138,000 tons) of timber and other forest products annually for international and domestic markets. Annual turnover is expected to be around $6 million. The operations will employ 70 local Aboriginal people.

This particular project has been seventeen years in the making. The harvesting concept started back in 2000, with Rio Tinto offering a Letter of Agreement in 2008, and the Queensland State government minister issuing a Letter of Support that same year to the Wik and Wik Waya community elders and leaders. The Operational Harvest Plan was finally secured in December 2016. Many detailed trials and studies were completed and a full Access Agreement with Rio Tinto was close to sign off.

Wik Timber S855D Shovel Logger

At that point, Jacky set about securing the most reliable and robust forest harvesting machines he could find for this very remote location. The result was the purchase of a 610E skidder as well as an S855D shovel logger equipped with the 5195 directional felling saw and the feller director boom system. The machines were delivered in August 2017 to Hey Point on the southern side of the huge Embley River.

Gina reports that “our first sales agreement is close to being finalised with Curly Tatnell Dale & Meyers Operations Pty Ltd. Dale & Meyers is expected to take Darwin Stringybark and Bloodwood sawlogs as made available by Wik Timber Holdings Pty Limited, up to a maximum of 3 500 tonnes for the remainder of 2017 and 25 000 tonnes in 2018.” That’s great news for the burgeoning operations.

In addition, Wik Projects has partnered with the University of the Sunshine Coast Tropical Forests and People Research Centre and the Queensland government to investigate the characteristics of the woodchip generated from land clearing for bauxite mining. Mark and his team are currently assessing the woodchip’s potential as a biofuel through gasifi cation, production of pellets, or other processes, in addition to the potential in mine rehabilitation areas to improve soils and rehabilitation outcomes.

Importantly, these options will be further considered for their Indigenous business and Indigenous employment outcomes. “Imagine if we can demonstrate that we can collect sawlogs for our sawmills, process some for veneer, utilize some logs for power poles and then utilize the rest as woodchips to generate electricity for Aurukun through Indigenous-owned business and replace diesel power generators.And all of this from forest resources that have been traditionally cleared and burnt for over 50 years,” says Gina.

Mark adds that his “inner Brisbane Stringybark Cottage is a show home for the high value timber that the Wik want to salvage: Darwin Stringybark and Cooktown Ironwood. These species are in the highest value categories and can be used for any construction purpose in housing. One of the beauties for the market,” continues Mark “is the range of colours from light gold colours suited to domestic markets through to the red timbers favoured by the China and Japan markets. These Cape York timbers provide that spectrum.”

With harvesting, transport and port access planning complete, the logging operations are now in their initial stages. Phil Turnbull (Onetrak territory manager for NSW, QLD, and NT), Brad Madden (Onetrak senior field service technician), Steve Green (Tigercat Australian product support manager) and myself arrived at the remote Hey Point operations along with the two machines for the three-day delivery and start-up trials.

Jacky stated after the delivery and start-up that the Tigercat machines were “very strong and well built” and that he was “very happy that he bought Tigercat.” Then he asked with a big grin on his face, “When are you guys going to start building mining and construction equipment?” Gina and her team spoke to many existing loggers around Australia before choosing Tigercat. The result was a recommendation to Jacky to invest in a brand name that – as an experienced mine clearing operator – he had never heard of. Once Jacky watched the 5195 equipped S855D falling these large, mixed eucalypt trees and then bunching them up for the nimble but powerful 610E skidder, he knew they had made the correct decision. Now a few months on, Jacky says, “The machines are running well and the Onetrak and Tigercat guys so far have been very good to deal with and helpful with our operations.”

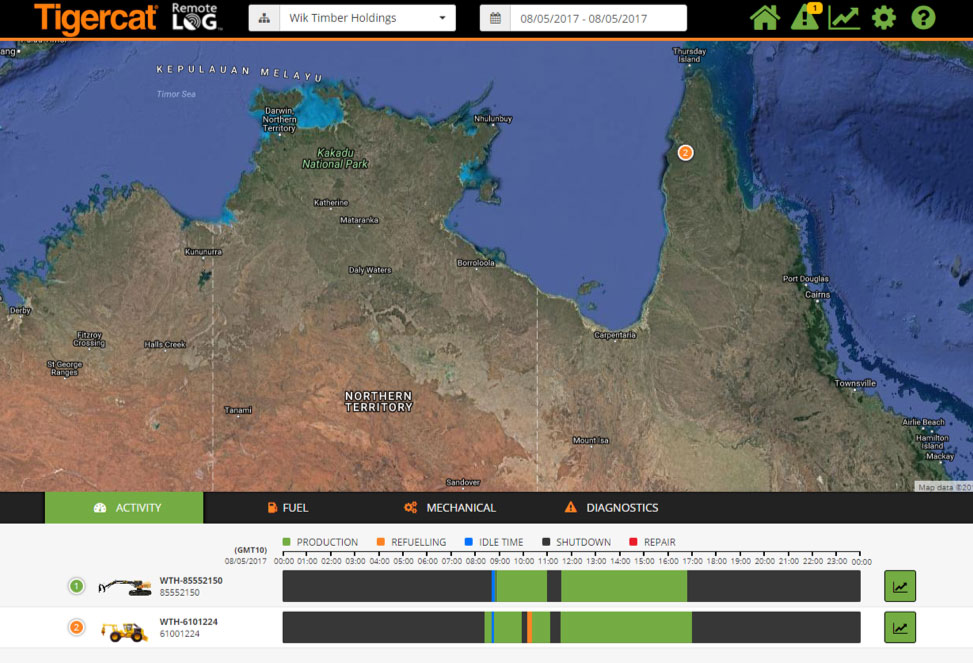

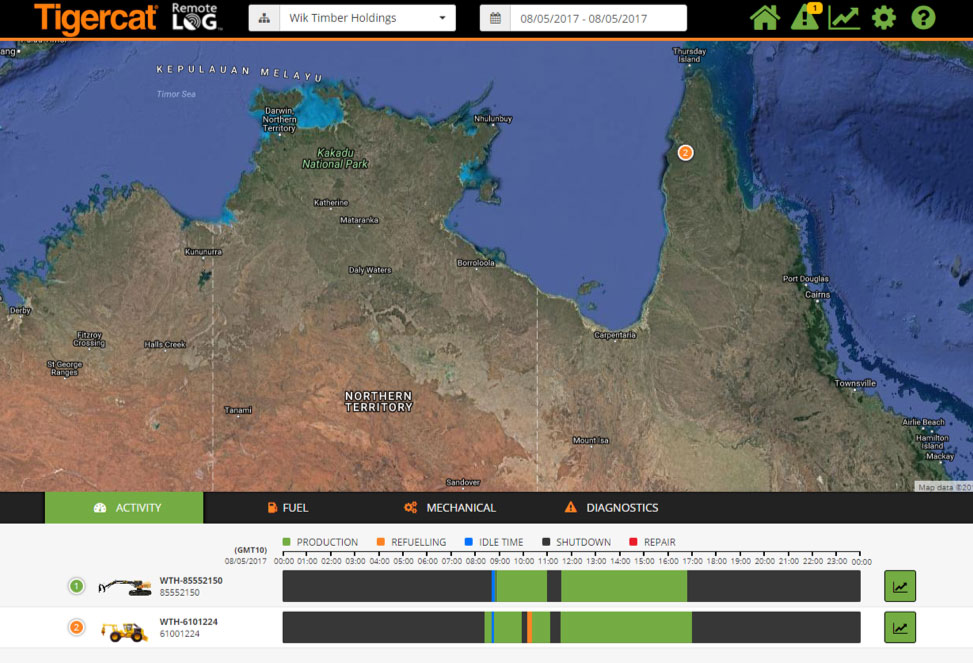

Remote logging operations require reliable machines. Tigercat’s new RemoteLogTM telematics system is also proving very helpful.

Both units are fitted with Tigercat’s RemoteLogTM telematics system, with real-time machine data relayed via satellite. The Wik Timber Holdings service and support team can monitor each machine’s working positioning, production and fuel efficiency at any time, as well as be advised immediately of any technical issues to proactively monitor performance. They can use the system to manage scheduled servicing and maintenance quickly and accurately.

The initiative and drive of the Wik Timber Holdings team is improving the education and long-term employment opportunities for the Wik and Wik Waya people. In addition, the team is leading the way with much improved management of the Australian northern mining leases by utilizing a sustainable and valuable forestry resource. The team is accomplishing all this while shouldering the additional and incredibly important cultural responsibilities. Perhaps this is just the tip of the iceberg for mining operational land clearing practices in Australia going forward.