4th August 2017

25 years ago, a very small company with a single prototype and no distribution showed up at a logging show in Georgia. What led up to it and what happened next? Some of the earliest Tigercat team members look back for the answers.

A young Ken MacDonald eagerly completed a four year Business Administration degree in two and a half years before joining MacDonald Steel full time as a production coordinator at age 22. He made it known that he wanted to purchase the company from his father. Ken explains that great pains were taken to ensure the valuation was independent and verifiable. For several months, accountants and appraisers evaluated real estate, inventory and equipment. The closing date was August 1, 1976 – the day before Ken turned 23. Between 1976 and 1989 Ken doubled sales several times over and quadrupled the employee count before a fierce global recession took hold in Ontario and began to cause serious harm to the company.

Ken MacDonald, CEO: I started work at MacDonald Steel when I was nine years old and I have basically been coming into the factory almost every Saturday morning since then. After graduating from university, I joined the company full time. Over the years, I have literally had hundreds of teachers and mentors both within the company and amongst our customers.

(L-R): Jon Cooper, Ron Montgomery, Rick Routliffe, Johnny Boyd, Stan Bera, Ralph Zuidervliet, Bruce Vaile, Tony Iarocci, Ken MacDonald, Martine Léveillé, Joe Barroso, Ken Harrison, Michael Fischer, Phil Ricotta, Dick Ronald, Don Snively, Grant Somerville.

Some taught me how to run the various machines, some taught me to fit and weld, some taught me how to drive forklifts, cars, trucks and tractor trailers. Some to scuba dive, some to climb heights and install equipment, some to estimate job costs, some to read drawings and financial statements. Some taught me to read people and to swear like a sailor. But all of them taught me the importance of teamwork.

Joe Barroso, VP manufacturing: I was a struggling student looking for summer employment in the summer of 1984. A friend of mine had just started working at MacDonald Steel and called to let me know they needed a second student. I went right over and was hired to start the next day. I was working in quality control and shipping/receiving when I started but soon was involved in many different functions within the plant. I worked there every summer until I completed school at which time Ken hired me on full time in the planning department.

Ken MacDonald: In the late eighties, MacDonald Steel lost a lot of core customers. This had near catastrophic consequences on the company and it forced me to look at alternatives. I bet the farm on starting work on a new product line and eventually creating a new business entity.

Tony Iarocci, president: In 1991 Ken approached me with a proposal to join his organization with the express purpose of designing and building log skidders. Although for a brief couple of years I was not involved in the forest industry, I did have over twenty years of experience in engineering, customer service and marketing while working at Koehring Waterous, a manufacturer of pulp mill equipment and state-of-the-art forestry machines. The thought of re-entering the forestry equipment business with a clean sheet intrigued me and I accepted Ken’s invitation.

Jon Cooper, VP engineering: I started working at MacDonald Steel in 1987. When Tony was hired to develop a forestry machine, I was assigned to produce drawings for the various machine concepts. After the wheel feller buncher was selected, I continued designing and creating drawings used to produce the first machines. During that time, Tigercat was created and I became the second ‘official’ employee.

Tigercat Equipment Inc. was established as a Canadian corporation January 20, 1992.

Tony Iarocci: We began designing the 726 in the fall of 1991 with a goal to have it completed and ready to exhibit at a live, in-woods show in Quitman, Georgia in April 1992. Although lacking some finishing touches, such as finding a location for the batteries, which we had temporarily secured with bungee cords under the engine, Don Snively loaded it on a MacDonald Steel truck and with Jim Wood, we set out for the southeast US.

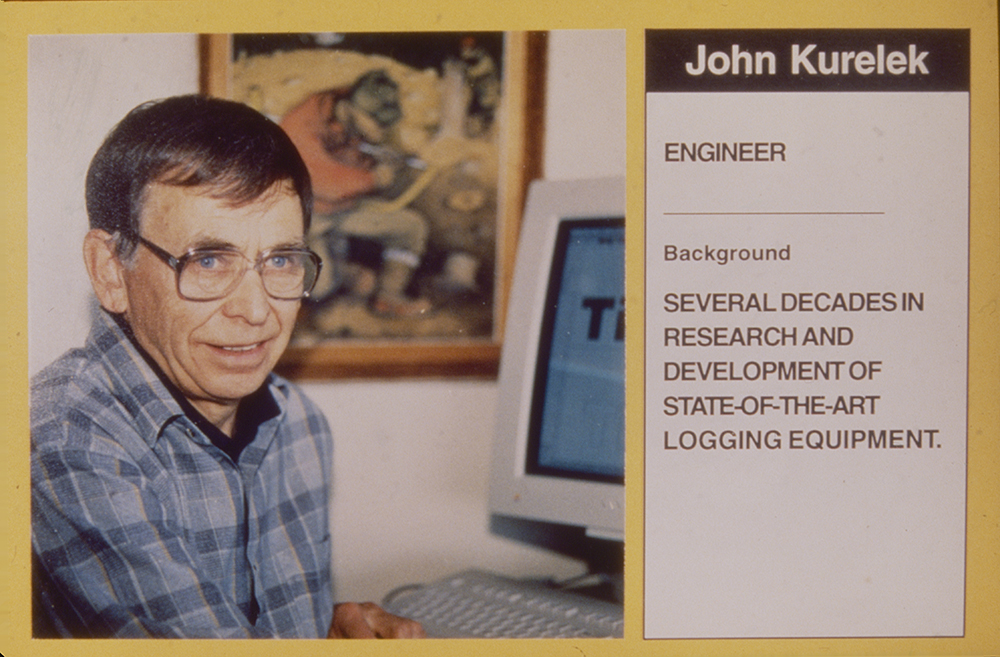

Jon Cooper and John Kurelek in the field with an early machine.

Jon Cooper: At that first show, a logger asked me how much the machine cost. I told him the price and a look of shock came over his face. He replied that the price must be wrong – he could buy two feller bunchers for that price. I assured him the price was right and tried to explain the extra value was in the machine. He left unconvinced and I was a bit worried for our future.

A few years later at the same show, a different logger approached and asked what I did at Tigercat. After I told him, he asked to shake my hand and thanked me for giving him his life back. He went on to say that he used to run another brand of machinery from Monday to Friday trying to make a living. Then he worked on that machinery Saturday and Sunday so he could go back to work logging on Monday. With his Tigercat machine (which was far from new) he could run it from Monday to Friday, park it and enjoy the weekend with his family – something he had never been able to do before. He said the Tigercat was worth every penny. It was reassuring to hear that the additional value was being recognized.

Ken Harrison, technical publications manager (retired): I worked at Koehring Waterous for about twenty years as technical publications manager. Later at MacDonald Steel, Tony and Ken got involved with producing logging equipment. After production began, Tony approached me to have some labels made for the first 726 feller buncher. I later joined Tigercat in July 1992.

Tony Iarocci: We had committed to a prospective dealer in North Carolina to demonstrate the machine in operation on our way to Georgia. We drove to a logging site in Lumberton and were met by the contractor who climbed into the cab, drove the machine off the side of the trailer and immediately proceeded to the block, intent on cutting trees. With difficulty, we managed to stop him, but only for the few minutes required to remove the saw blade guard. As soon as the guard was off he resumed his quest to cut trees. Jim, who lead the assembly team and Don, who drove the truck, had never before seen mechanized harvesting. They observed incredulously this machine in operation. The logger continued, disappearing into the forest for what seemed an eternity. He liked the machine.

Don Snively, now a district manager and US citizen residing in Georgia with his family, was a truck driver at MacDonald Steel in 1992. He toured the prototype machine around the US for forty days until it found a home at Williston Timber in north Florida.

Don Snively, district manager: When Jim Wood and I saw the 726 cut its first tree we said, “Damn, it works.” We had never seen a machine cut a tree and carry it.

Dick Ronald, US sales manager (retired): I had spent 27 years working in the heavy equipment business for Clark and then Valmet – mainly in the forestry end of it. Tony was looking for somebody, and I think a few of the dealers who Tony was working with and who knew me quite well, were advocating for me to get a job there.

Ken Harrison: Changing the company name from Tigercat Equipment to Tigercat Industries back in 1993, moving into our own facility on Plant Farm in Brantford, that was all very memorable for me.

Grant Somerville, VP engineering: Our early days were spent at the Industrial Road plant, but in 1993 we moved into our first ‘Tigercat’ factory in Brantford. I recall thinking we had achieved our ultimate goal, our own factory. What more could we want? We had no idea that was just the beginning of our growth.

In just five short years, Tigercat shipped its 1000th machine in 1997. The loader group is shown here in front of Tigercat’s first dedicated plant, 86 Plant Farm Blvd, Brantford.

Ken acquired Plant Farm in 1993 and then went on to purchase additional disused buildings in Paris, Brantford, Woodstock, Cambridge and Kitchener over the years.

Ken MacDonald: I get a big kick out of transforming older, pre-existing buildings into new manufacturing facilities for our purposes. I had a great time participating in the planning and construction of the newest plant we built in Paris. It has also been fun installing many new, state-of-the-art machines, cranes, and grit blast and paint booths over the years.

Dick Ronald: It’s kind of humorous, when I look back at it, because we were doing everything at Tigercat at the time. You know, along with looking after sales and courting new dealers and all the rest of the stuff that goes on with that business.

Ken Harrison: In the early days, I began preparing parts and service manuals, spec sheets, company forms and the company logo as it is today. I was also dealing with service calls from dealers over the phone. Later, I focused primarily on being the Tigercat technical publications manager.

Tigercat’s original assemblers, like Jim Wood, Ralph Zuidervliet, Larry Almond, Tim Koniuch, Ross MacDonald, John Stevenson, Bill Clark, Denton Rerrie, Ernie Sowden and Paul Brown were highly skilled tradespeople who could solve problems on the fly. Tigercat needed people like this. The young company did not have the production controls, drawings or documentation that exist today. The machines were assembled from start to finish by teams of two. The assemblers names were imprinted on a label in the cab. Proudly built by…

Ralph Zuidervliet, assembler (retired): I was unemployed and received a phone call from Tony whom I had worked with at Koehring Waterous previously. At that time, I was 62 years old and a skilled worker trained in Europe and also in Canada. Mr. Iarocci was familiar with my work. He knew I was unemployed and asked if I would be willing to come and work for him at a new company called Tigercat.

Grant Somerville: I began working in forestry in 1977 in the Canadian pulp and paper side of the industry. Forestry was done on a large scale with fleets of large machines and unionized workforces living in remote, well-outfitted camps. The decline of the Canadian pulp and paper industry led to the demise of company-owned and operated forestry operations, and with them the market for the large machines we were building. By the mid-eighties it was apparent the future was with smaller, private contractors. These new customers needed smaller scale, more affordable machines. This accelerated development of the track feller buncher. By the early nineties, many manufacturers were offering models to the market and competition heated up. In 1993, the competitive structure created a window of opportunity for us. The resulting 853 track feller buncher – distributed in Canada through the Deere dealer network – played a key role in Tigercat’s early development.

The ribbon cutting ceremony for the opening of 54 Morton Ave in Brantford in 1998. The crowd is waiting for an operator to get into the machine and cut the ribbon Tigercat-style.

Tony Iarocci: The 726 created the foundation upon which Tigercat would develop to become a respected, major global provider of forestry machines. It essentially paved the way for additional models and the 726 did not go unnoticed by John Deere, one of four competitors offering drive-to-tree feller bunchers. The success of the 726 prompted Deere to approach us in 1993 with a proposed marketing agreement. Tigercat would build a yet-to-be designed Tigercat branded track feller buncher and make it available on an exclusive basis to all Deere construction and forestry equipment dealers in Canada. Grant Somerville headed the engineering development of this new model, the Tigercat 853E. The model designation was actually requested by Deere. The prototype 853E was shipped to BC only a year later in 1994 and sold to Blue Nose Logging. We had done it again. The 853E was very successful and the expansive Deere dealer network gave us immediate coverage across Canada.

Martine Léveillé, service and warranty manager: My father worked for the John Deere dealer in my home town of Amos, Quebec. When I finished university with mechanical engineering, the dealership had received their very first Tigercat machine, an 853E feller buncher. The late Len Arvelin was at the dealership to introduce the machine and he suggested to my dad that I should apply for a job at Tigercat. Two weeks after I sent in my résumé, I received a call from Tony. He was visiting a dealer in Timmins and asked if I could meet him there. I went, and two weeks later, I moved to Brantford. My first day was September 25, 1995.

James Farquhar, district manager: I was able to spend a lot of time with Tony and learned a lot from him when I was running the parts department and later after my move to service. He also helped me by directing me on what night school classes to take – I spent almost five years going to night school. I still learn a lot every day working at Tigercat.

Brian Jonker, parts manager: My father was a welder for MacDonald Steel and became one of the earliest employees at Tigercat. When I finished school, I started with Tigercat in 1996 and spent my first year building cabs before moving into the parts department, which at the time consisted of myself picking parts and Jim Leach and James Farquhar in the office. Tony gave me an opportunity at a young age to grow into my current role. There were many things to learn and he guided me in the right direction, while also allowing me to occasionally bump my head.

Johnny Boyd, district manager: I’ve been with Tigercat since December 1995. At that time, we had an 1800 shear, a 2000 shear, the 726 and 720 and the 853 and 845 track feller bunchers. I’ve often said to people who don’t know Tigercat, that it is an engineering-based company that will allow ideas to develop into products for niche applications all around the world. We don’t have to convince some accounting or marketing group within the company in order to satisfy an end user in need of a better tool for a specific application. The best thing about Tigercat is that we can decide overnight to build a superior product for anyone in the world.

Like many of the designers at Tigercat, Duane Barlow came on board as a co-op engineering student.

Duane Barlow, product manager, attachments: John Kurelek was a major influence. I worked under his direction for the shear head and later the high capacity bunching head development. John was a key innovator in the industry, but also wanted things strong, simple and woods-tough, a mantra that still holds true today.

John Kurelek is an industry veteran and pioneer who went to work for Marathon Corp. in northern Ontario in 1951. Later, in his career at Koehring, he was integral in the development of the shortwood harvester, the accumulating shear and the disc saw. At one time or another Robin Barker, Stan Bera, Ken Harrison, Tony Iarocci, Kevin Keats, Phil Ricotta and Grant Somerville all worked for John at Koehring. These individuals would later become key team members at Tigercat. John’s influences have been crucial to the success of Tigercat.

John Kurelek, senior engineer (retired): To be a success, our ideas have to work, they must answer a need with a good job and they have to make money. Our team of three knew that our machine had to be better and that our best chance at that was in durability. One had but to look at the weld repairs on relatively new [feller bunchers] in the bone yards of southern dealers to see that there was opportunity.

Taken from an old slide deck in the mid-nineties.

Johnny Boyd: John Kurelek had the most influence on my thought process. He said, “When thinking of productivity, don’t think about an hour, don’t think about minutes, think about seconds, because seconds make minutes, minutes make hours. The way to increase productivity is to save seconds.”

Ralph Zuidervliet: Training new people was something that stands out in my mind. Each new person I trained was a legacy for me and the company. I recall that one of the guys I trained received a 50-dollar bill from an American customer during a plant tour. The customer was impressed at the high quality and workmanship of his machine. It was nice to know I helped contribute to that young man’s success and that he would continue the tradition of fine craftsmanship and quality that Tigercat had come to be known for.

The customer had noted the names of the assemblers who had built his machine and sought them out during the tour.

Ralph Zuidervliet operating the hydrostatic demonstrator.

Ken MacDonald: I take great pleasure seeing young people join the company and grow as individuals, get their first cars, live through the dating years, marry, raise a family and rise to the best that they can be in their trade or profession.

Brian Jonker: I would challenge anyone to tell me a company that cares about its employees more than Tigercat. That starts from the top. Ken has always thought about his employees, dealers and customers first. That shows through. We have grown into a large company but the personal touch has never changed. Ken is a great example for all of us. He truly cares about others.

Martine Léveillé: I had the incredible chance and honour to work with my father, Yves, for eight years when he joined our team as district manager for Quebec in 1998.

Tigercat has long-term dealers in the southern US like Tidewater and B & G Equipment that helped the unknown upstart to establish credibility and some market share. And Tigercat contributed to the success of its dealers by eventually providing a full product line as equipment manufacturers consolidated and some competing product lines were swallowed up or disappeared altogether.

Dick Ronald: One Tigercat dealer that stood out was B & G Equipment. I’ve known them a long time because when I was at Clark, they were signed up to become a skidder dealer. They had a two-car garage in Philadelphia, Mississippi. They were selling truck and trailer parts and a sales rep we had down there went and called on them to see if they were interested in selling skidders. Debbie and Doug [Bates] were both in high school. That’s when I started going down there. I still remember Peggy’s Restaurant in Philadelphia. What a success B & G has been. There’s not many dealers who have stayed around in the forestry end of the business that long and done that well.

Ken MacDonald: Growing our dealer network has afforded the chance to meet interesting people from around the world. We sure as hell have the good fortune to work with some of the most progressive, inventive industry leaders – many of whom are real characters with unique personalities. They all work hard and most of them can party like there is no tomorrow.

Dick Ronald and Martine Léveillé on site at DEMO 1996 in Quebec.

Martine Léveillé: DEMO in Quebec City in 1996 was my first live logging show. I was translating for everyone, presenting at the show with Dick Ronald and entertaining our visiting staff and customers after hours in beautiful Old Quebec City. Don Snively and I travelled back from the show together. He unknowingly taught me how to drive on a four-lane highway. He asked me to drive so he could make phone calls. I didn’t tell him at first that I had never driven on the highway before. You should have seen his face after I said that – a priceless moment.

Brian Jonker: I remember in the first month as the parts manager going to the woods in Florida. Seeing snakes and alligators and witnessing the heat the operators worked in opened my eyes to the conditions our customers endure.

James Farquhar: I found myself laying in a skidder in the pouring rain in Chile. I was trouble shooting and I needed a 10 mm wrench. I was contorted into the belly of the machine yelling for a 10 mm wrench. No one got me the wrench. No one on the site spoke English. After climbing out of the machine, my Spanish was certainly no better, but they all knew the word wrench.

Grant Somerville: We drove through a rural village in Tasmania, a few homes around an intersection of country roads. The local dealer rep driving us stopped in front of a modest general store and said we should pick up some sandwiches for our day in the bush – it was the best place around. As it was the only place around, I had low expectations. I went inside and was immediately taken by the age of the woman standing behind the simple wooden counter. She must have been well into her nineties. Trying to be amusing I said, “I hear you have the best sandwiches in the world here,” to which she replied with no expression and great confidence, “Yes we do.” This struck me as a bold statement. While you can’t judge a book by its cover, she gave the impression of spending her years within walking distance of that store. I kept my chuckle on the inside and respectfully ordered lunch. Later when we were eating I realized she was neither backward or arrogant. She was right. At first, people thought our wheel feller buncher was a little funny looking. You really shouldn’t judge a book by its cover.

Dick Ronald: I remember flying down to Georgia or some place in Ken’s plane one day and it is kind of bouncy. He had a storm scope so you know where the storms are. Air traffic control comes on and suggests we have to deviate around the storm and Ken looks at the scope and says, “Nah, it’s okay we’ll shoot straight through.” Well we had to hold our briefcases down so they wouldn’t hit the ceiling but other than that it was okay.

Ken MacDonald: I am a religious person and I strongly believe that God helps those who help themselves. I believe that if we work both smart and hard, things will work out. Another aspect of my faith is belief in my team. I have always felt that if anything can be done, my team can do it better. To date they have lived up to and often exceeded the level of faith I placed in them. Have we fumbled from time to time? Hell yes. But do we continue to strive to be the best? You’re damn right we do. A directing philosophy for me and the company is to treat others the way you wish to be treated. We try to instill that way of life in what we do as a company.

Another thing in my life that perhaps has been an influence is a favourite children’s book. The title, I think, is The Little Engine That Could. Tigercat has been, and will continue to be for decades to come, among the smallest of companies in most of the markets we compete in. We and our dealer partners have no choice but to try harder to design and build the toughest, most reliable, most productive machines. We have to work even harder to provide the very best after sale support to our customers. The giant companies we compete against are always looking to eliminate us.

Duane Barlow: Tigercat has achieved so much, ER, the hydrostatic skidder. But for me, the development of the high capacity bunching shear and disc saw heads stand out. They significantly improved productivity – particularly for plantation applications. Adding snouts and closing off the unguarded chip discharge enhanced safety – something we have tried to emulate in our bar saw heads by limiting openings directly in line with the chain.

John Kurelek: Heads made by others had been installed to work on Tigercat feller bunchers. They all had at least one tree taking arm and one opposing tree tucking arm – a taker and a tucker. And to various extents, a pocket to place tree butts in out of the way of severance. Bundle building in the pocket was not reliably neat. Sometimes trees would jack straw. Tigercat’s tractors were quick and forceful. They could lift and carry heavy bunches and travel backwards and forwards to get to more trees. Under such work loading, life of existing felling heads when mounted on Tigercat tractors was short, so a stronger design was needed.

Ralph Zuidervliet: In my view, one of the best things the company has made were all of the felling attachments. They were very well made and it has become something the company is known for.

John Kurelek: I recalled how often the bundle alignment was spoiled by the tucker when it pulled out from behind the tree and moved it before re-grabbing it. Part of the problem seemed to be that with the arms pivoted on opposite sides of the storage pocket, each would tend to have its own preferred place to put the tree. My thought, which we put into hardware and tested, was to pivot both taker and tucker on approximately the same axis so that they would each tend to push trees into the same place in the pocket.

Jon Cooper testing the 1185 harvester launched at Elmia Wood 2017. The original 726 and the new 1185 are at opposite ends of a very broad spectrum in terms of design, size, technology, function and just about every other factor except durability and reliability. Jon has led the drive-to-tree feller buncher, skidder and cut-to-length product groups over the years.

Jon Cooper: We just finished the first shear head and had sent the machine to a logger in North Carolina who agreed to test it on his thinning job. He was running five competing feller bunchers to meet his production needs. He parked one and had the operator run our machine. It was an impressive job to watch. All five machines would enter the stand together and cut to the back of the stand. Then they would drive out the cut row, emerge together at the roadside, move down the road and enter the stand again. We left the machine for a few days, then came back and asked him how it was working. He said it really did not seem to be doing any better than the others, but that it was keeping up okay. We were disappointed but the contractor purchased the machine.

A few months later we came back to the job. As we drove in we saw two of the feller bunchers parked. The contractor told us he didn’t need them – he could make the same production with only three machines. He recounted to us that one day he snuck into the woods. He watched the Tigercat cut wood way faster than the other machines. The Tigercat would reach the back of the stand in half the time. Once it got there the operator stopped, lit a cigarette and waited for the other machines to catch up. After a stern chat with the Tigercat operator, the contractor parked the two machines. The shear dramatically changed the productivity of wheel feller bunchers in thinning applications.

Dick Ronald: To attract dealers, you have to have a full product line. Tony never really wanted to build a skidder but we had to have one to fill out the product line to keep the dealers happy. If you have a full line, you’ve got the dealer’s attention and you haven’t got someone else in there trying to worm into your business.

Tigercat rounded out the product line with a skidder in 1996 and a knuckleboom loader in 1997. This gave US dealers a product line. However in Canada, it created the necessity to establish a parallel dealer network. Corporate Deere was happy to allow its dealers to sell the non-competing 853E feller bunchers. Skidders… that would be another story. Strongco got the first kick at the can.

Jon Cooper: Our customers and dealers began to ask for a skidder. After a few years of success with feller bunchers, they told us that if we could develop a skidder that was as good as the feller buncher, it would be a success. Market demand drove the decision to develop a skidder. It was similar logic that led to the loader development.

Johnny Boyd: The Tigercat skidder has done more to change productivity in the southeastern US than anything in the last twenty years. Only one thing defines the productivity of a skidder and that is the size of the grapple. Speed doesn’t matter. It’s what you bring to the roadside when you come. We’ve been able to increase the grapple size and put everything in front of the grapple to do the job.

When Tigercat launched the 630 skidder, it was the biggest machine on the market, competing in the size class with the smallest market share. These days, it would be about equivalent in size and capacity (but certainly not speed) to the 610E, Tigercat’s smallest grapple skidder. Tigercat called it early and led the trend toward bigger skidders.

James Farquhar: The move to big skidders was a pretty big deal. I have a customer that told me that if we sold him the 632E twenty years ago, he would be retired by now.

Joe Barroso: There was a gentleman by the name of Rick Duke and he worked in one of the Brantford plants. He had been laid off but Tony suggested I call him back to work at Savage Drive and see if he could be of help in our process improvements. I was looking after the skidder line at the time and Rick was my first real introduction to lean manufacturing. Together we were able to move the organization in dramatic fashion toward a lean operation. It made a significant change to Tigercat.

Tony Iarocci: The introduction of electronics in off-road equipment has had a major impact in the evolution of forestry machines. The first Tigercat models did not have one electronic component. Although, the introduction of electronics in engines, hydraulic controls, telematics and exhaust emission systems has introduced a great deal of complexity in forestry machines, the industry has benefited with operator safety and comfort, improved performance, a significant reduction in fuel consumption and greatly reduced emissions.

Tigercat’s last go at the Atlanta show. Downtown Atlanta wasn’t the most logical choice of venue for a logging equipment show. The Tigercat booth staff did not blend in with the crowd.

Joe Barroso: From an operations perspective, we have been able to reduce the assembly times by 75% and we have reduced inventory by 80% on a majority of items. This has been a very significant change to the manufacturing process that occurs in a Tigercat plant. We continually improve on quality, delivery and cost.

John Kurelek: I think of [the ER] invention as the best of my career because it will surely continue to save our planet thousands of truck loads of fuel. When the Drott excavator based feller buncher was first conceived and produced in the fifties, its energywasting hydraulic system was implanted in [the] industry for a half century. The ER circuit provides a way to transfer the pressurized oil in the base of the hoist cylinder to the base of the stick cylinder where it continues to do load supporting work. This transfer of pressurized oil is done by operating a single lever so it is easier to train operators. Engine power is not used to pump oil under pressure during reaching and can be used to hurry other machine functions or it can simply be fuel saved.

Grant Somerville: The way we work with the people that use our machines is where we are different from the mainstream. Many companies claim to be in touch with their customers, but very few ever really achieve this. The fact that we have successfully made this a key part of our business model is a major accomplishment I think many may not realize. Customers may be surprised to learn just how much they have contributed to the development of our products.

Joe Barroso: For me, the best thing about Tigercat is probably the ability to create and invent and not be tied down in bureaucracy and red tape. You can create solutions, problem solve with your team and make things happen as quickly as necessary. It could be one of our significant competitive edges.

Ralph Zuidervliet: Management, engineers and my fellow workers all contributed to an outstanding work environment. It was quite a close knit group. Like family. The camaraderie, the clean, safe environment, the support of our engineers and management. I will always remember my time at Tigercat fondly.

Brian Jonker: The vision of a few people building that first machine has led to where we are today. From Tigercat employees to our dealers, customers and vendors, there are tens of thousands of people whose lives are directly affected by Tigercat. That is very impressive and powerful when you stop and think about it.

Ken Harrison: I came to Canada from England in 1971 and retired in 2004. I can honestly say that I got it right twice. I came to the best country in the world and I worked at the best company in the world.

Ken MacDonald: What we have accomplished to date is simply the beginning of a machinery design, manufacturing and product distribution organization. It is the foundation for what is to come. We have so many more products to develop and so much more we can offer to the world. I recognize that we will face more than our share of challenges but I continue to have faith in our team, in their desire and capability to succeed far beyond my lifetime.

Tony Iarocci: Unquestionably Ken’s incessant desire for ever-increasing growth, in terms of both sales volume and product offering, has had a profound influence on my day-to-day decisions and long-term strategies.

Ken MacDonald: I am overjoyed that the world record holders for harvesting and extraction and almost all of the top loggers and forestry companies already use our equipment. I find the greatest pleasure in working with them to create the optimal harvesting solutions and seeing them succeed.