– Tony Tijerina

Reprinted with permission, Timber Harvesting, July/August 2011.

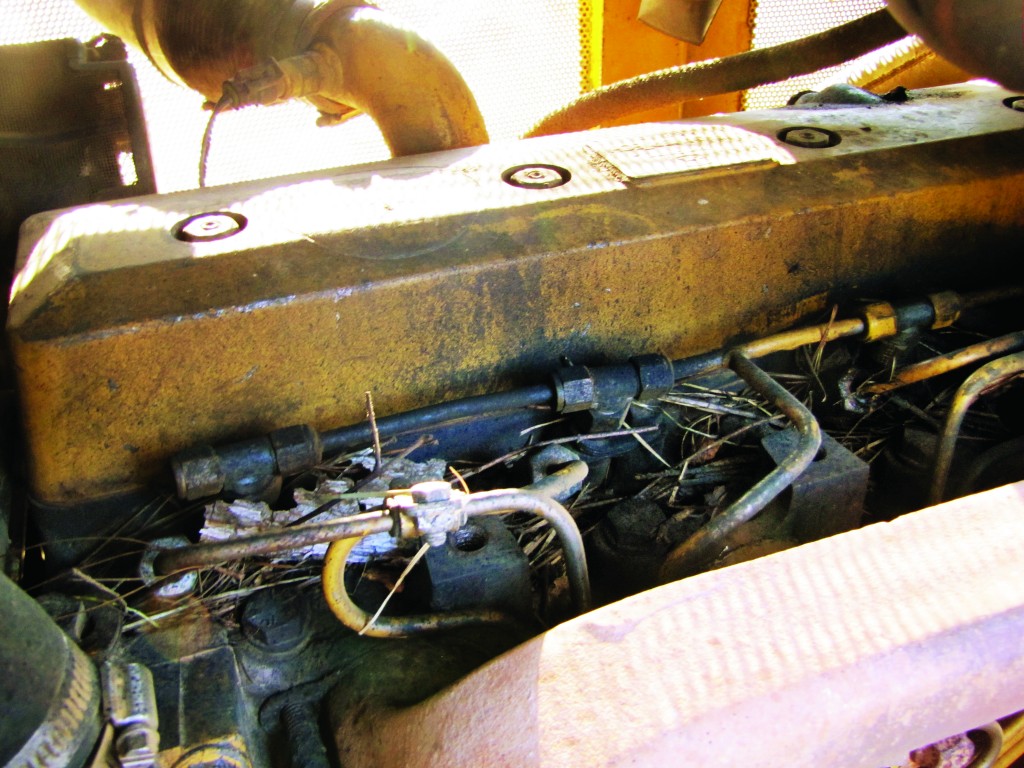

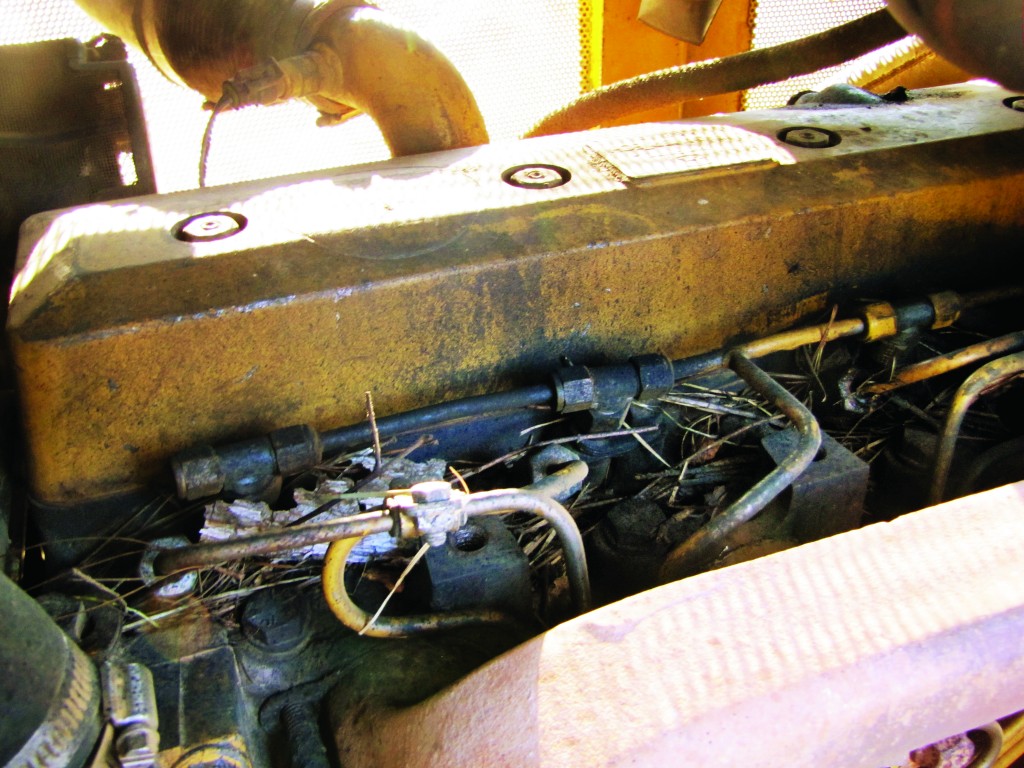

Removing debris near the engine manifold and turbocharger is a must.

Article after article has been written about the importance of equipment maintenance but often loggers pay little attention to them. With the production pace now slower in much of the country, most loggers have the time to get serious about preventive machine care. To use the old cliché, there is no time like the present.

Skidders, fellers, loaders and other equipment represent the largest expense you have as a logger. Without these important assets you are out of business. Therefore it is imperative that you stress upon your supervisors and employees the importance of keeping equipment in top condition.

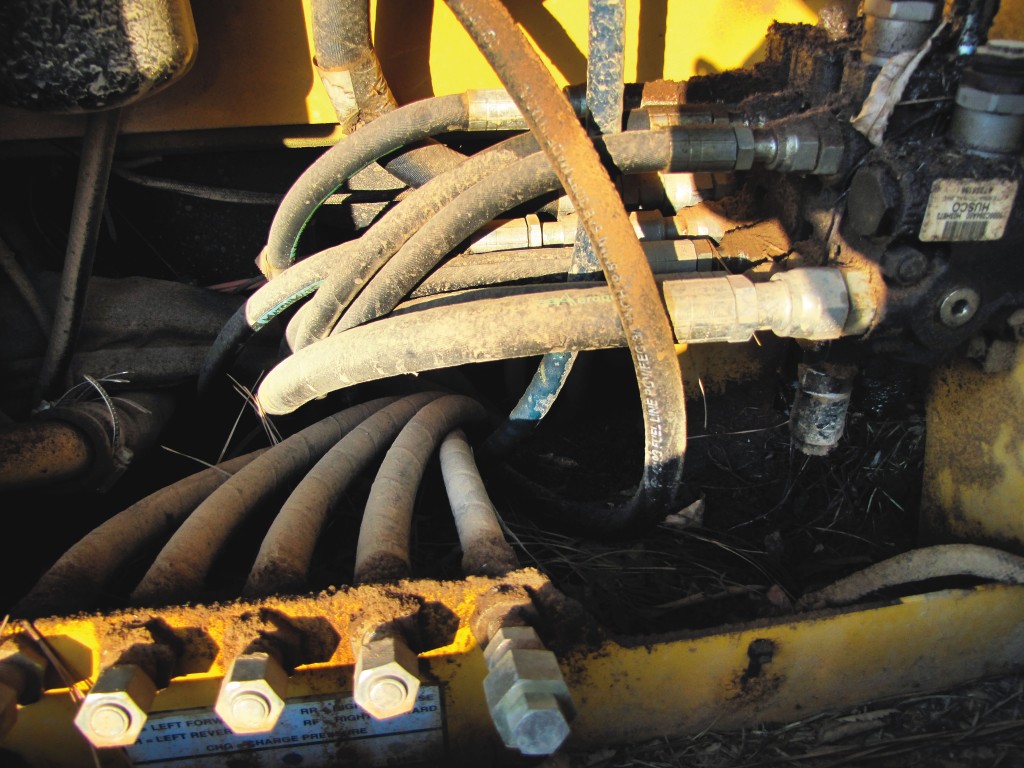

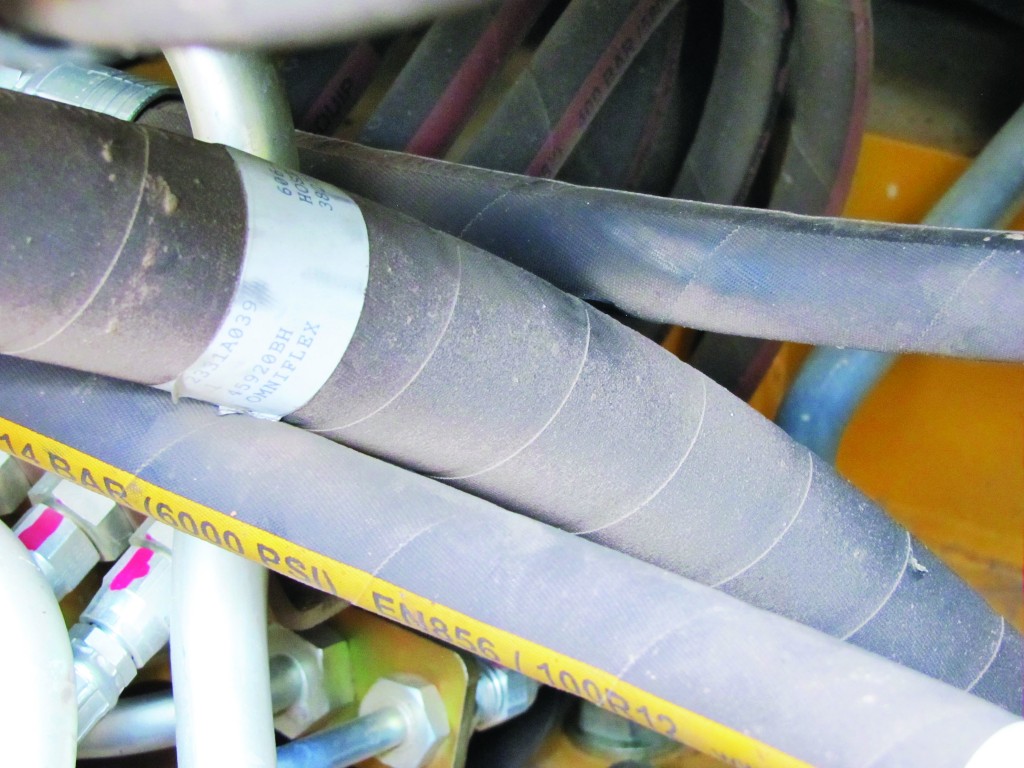

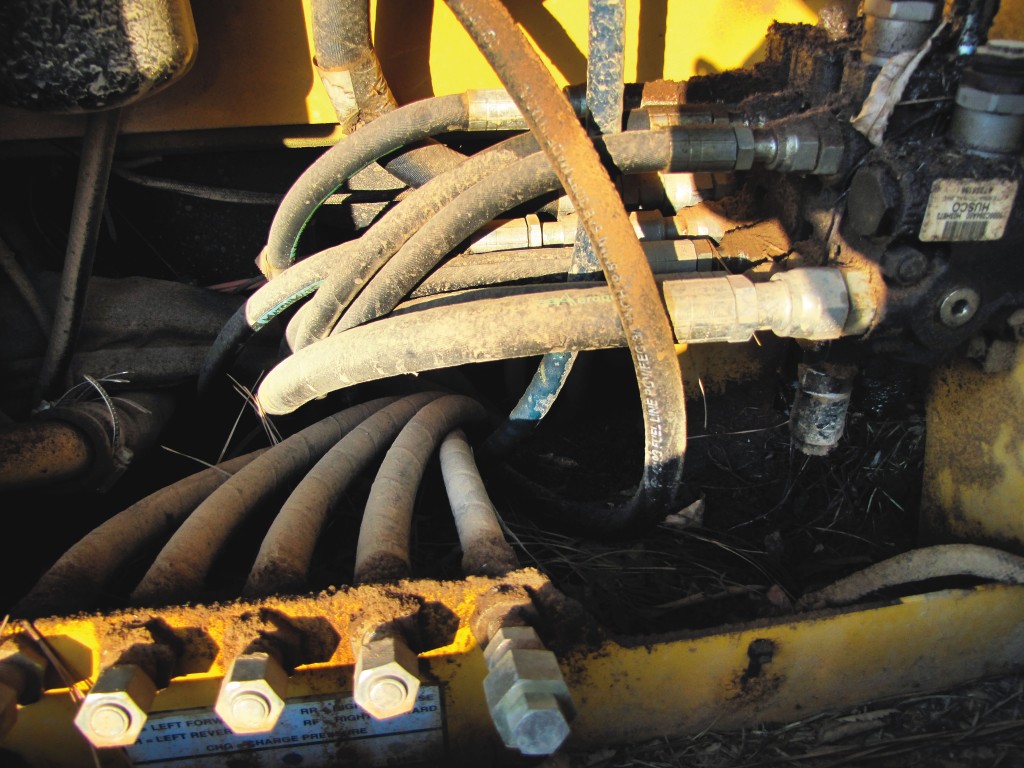

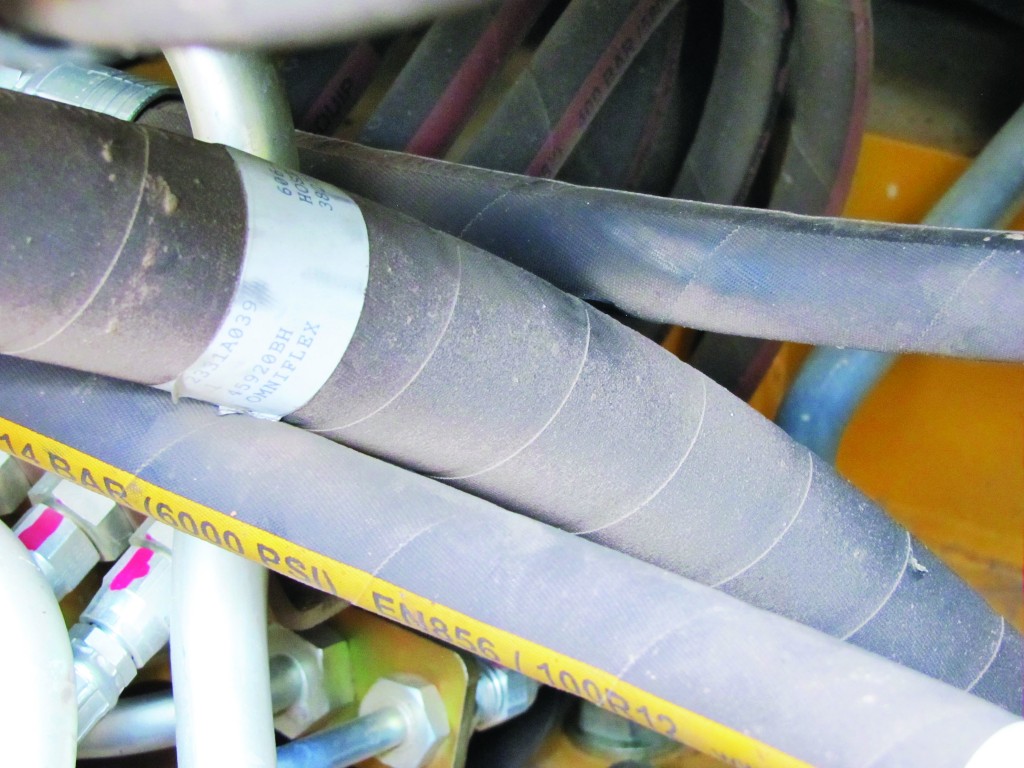

Hoses can be weakened by rubbing, chafing and pinching. Hoses leaking hydraulic fluid near high sources invite trouble.

A daily equipment pre-start inspection should be conducted on each machine. This is your business and you decide who will be responsible for conducting the inspection. I recommend that the operator inspect, document and ready the machine for the day’s work.

The inspection should include:

Fluid levels. All fluid levels should be checked to ensure that they are at the proper mark so that the machine can operate in top condition. Low fluid levels cause early wear on parts and can create friction hazards.

Wiring. All wiring should be inspected for wear, abrasion and bare spots. It goes without saying that bare wires coming into contact with each other or metal will cause an electrical short and potentially a fire.

Hydraulic hoses. These are often overlooked during an inspection. These hoses are designed to operate under heat and pressure but they still require regular monitoring. Rubbing, chafing, pinching and mechanical injury can occur while the machine is in operation. The result is weakening of the hose, compromising the integrity of the line and reducing the pressure that the hose can handle. Hoses should also be checked for evidence of leaking. Hoses found with any of the described problems should undergo a more thorough inspection and be replaced immediately. Hydraulic fluid normally has a flash point of 2 270ºC (4,400ºF). While heated and under pressure the fluid’s flash point is dramatically reduced.

Hoses can be weakened by rubbing, chafing and pinching. Hoses leaking hydraulic fluid near high sources invite trouble.

If sprayed directly on the manifold or turbo charger, fire is very possible. All too often, a leak or problem is identified and repairs put off, only to have a burst hose cause a machine to catch fire. In addition to running the risk of higher insurance costs down the line, preventable fires like this cost the owner downtime, an insurance deductible and lots of frustration.

Manifold and turbo charger. This area of a machine poses the highest heat danger. Temperatures exceeding 4 260ºC (8,000ºF) can easily be found along the run of the manifold and at the turbo. These areas should be inspected every morning and any debris noted should be removed while the machine is cool and the debris can be safely removed.

The area should be inspected after shutdown. If debris has accumulated it can be removed with compressed air or the operator can wait until the machine has cooled down and it is safe to reach into these areas. Unfortunately, manufacturers have not been able to completely engineer out debris accumulations; however, they have come a long way.

Debris. Logging equipment is operated under dirty conditions. Forest debris is a constant menace. It presents a considerable fire hazard when in contact with areas that reach a potential ignition temperature of approximately 2 320ºC (4,500ºF). Debris accumulations should be monitored daily and removed often. Best practice is to remove the debris by hand daily and to remove it completely at least weekly. Don’t forget to remove debris accumulations from the

belly pan. Debris accumulations can and will provide additional fuel in a fire situation.

Articulation joint. Debris accumulates in the area under the cab. If left it poses a potential fire hazard and should be included on the daily inspection routine. Fire is a real danger in the logging industry. In my twelve years inspecting equipment, and investigating fires in equipment, it is evident that not every fire can be prevented. However, with diligence and effort, fire incidents can be reduced.

It is imperative that every logger has a plan of action to deal with fire. Employees should be trained in the proper use of fire extinguishers and water tanks. All too often I have asked an operator to pretend there is a fire on the machine and watched as he tried to locate the extinguisher and/or attempt to get into the water hose compartment, only to find it cannot be opened.

Fire extinguishers and water tanks need to be inspected daily to ensure they are ready for duty. When a fire occurs and the extinguisher is discharged, or there is no pressure in the water tank, you have no defense.

Removing debris near the engine manifold and turbo charger is a must.

In case of fire

All operators and employees must be trained and ready in the event of a fire emergency. At the first sign of fire:

1) Shut the machine down! This stops the flow of fluids under pressure.

2) Sound the alarm! Get help on the way.

3) Exit the cab and dismount the machine with fire extinguisher in hand.

4) Assess the situation from a safe location on the ground. Locate the fire. Personal safety is always first.

5) If it is safe to do so, spray extinguishing material at the fire through screen openings or other access points.

6) Only if safe to do so, remove screens or open doors and continue applying with a side-to-side motion.

7) Apply water to debris in belly pan to cool the debris and stop the fire from re-igniting.

8) Report the fire immediately to local authorities and your insurance company.

A good daily inspection program can and will assist in the reduction of fire losses as well as reduce operating costs by locating and eliminating costly leaks and problems. Every logger should develop and implement a policy requiring that all equipment be inspected and maintained. Records of the inspections should be kept to document that this work has been completed properly.