Ask an Expert

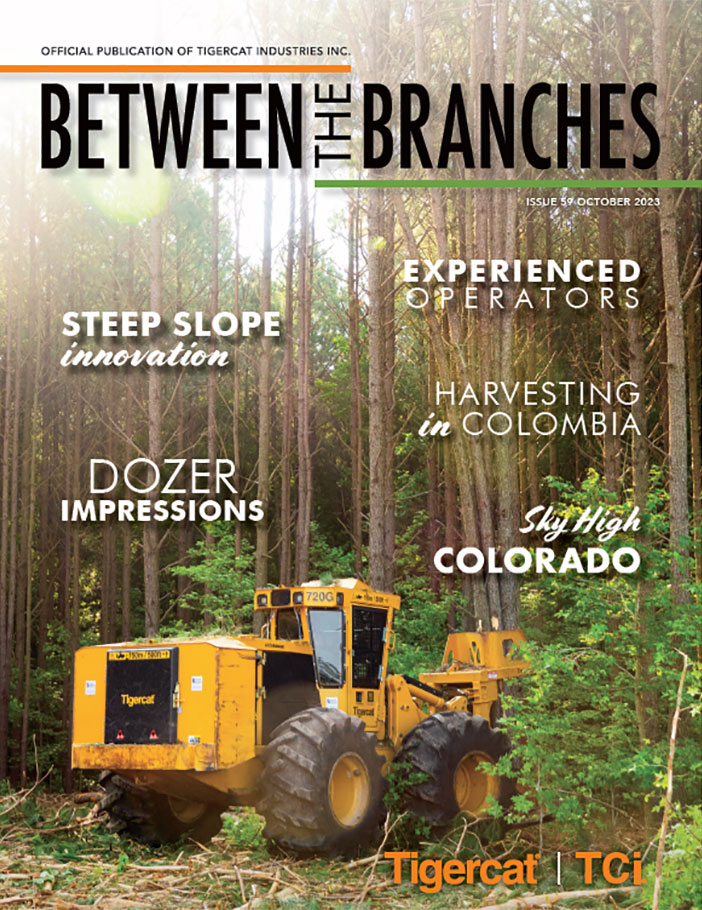

Experienced Operators

Steep Slope Innovations

Dozer Impressions

Harvesting in Colombia

Sky High in Colorado

Expoforest Brazil

Experienced Operators

Steep Slope Innovations

Dozer Impressions

Harvesting in Colombia

Sky High in Colorado

Expoforest Brazil

Roland Murphy has spent a lifetime in the Virginia woods. His invaluable experience, strong work ethic, and passion for the job enrich his coworkers and contribute to a successful, high quality logging operation. READ MORE

Guest contributor, Ryer Becker, talks about timber harvesting in the northwestern US and how productivity, safety and sustainability have been positively impacted by advances in equipment and technology. READ MORE

Guest contributor, Ryer Becker, talks about timber harvesting in the northwestern US and how productivity, safety and sustainability have been positively impacted by advances in equipment and technology. READ MORE

Guest contributor, Ryer Becker, talks about timber harvesting in the northwestern US and how productivity, safety and sustainability have been positively impacted by advances in equipment and technology. READ MORE

Jon Cooper is VP engineering for CTL products at Tigercat. He explains some of the unique design features of the 1165 harvester and how these features are benefitting harvesting contractors. READ MORE

BTB visits a unique high elevation logging operation in Keystone, Colorado. READ MORE

BTB visits a unique high elevation logging operation in Keystone, Colorado. READ MORE

BTB visits a unique high elevation logging operation in Keystone, Colorado. READ MORE

South Carolina contractor pulls the trigger on a TCi 920 dozer. His purchase decision is based in large part, on the strength and reputations of Tidewater Equipment and Tigercat Industries. READ MORE

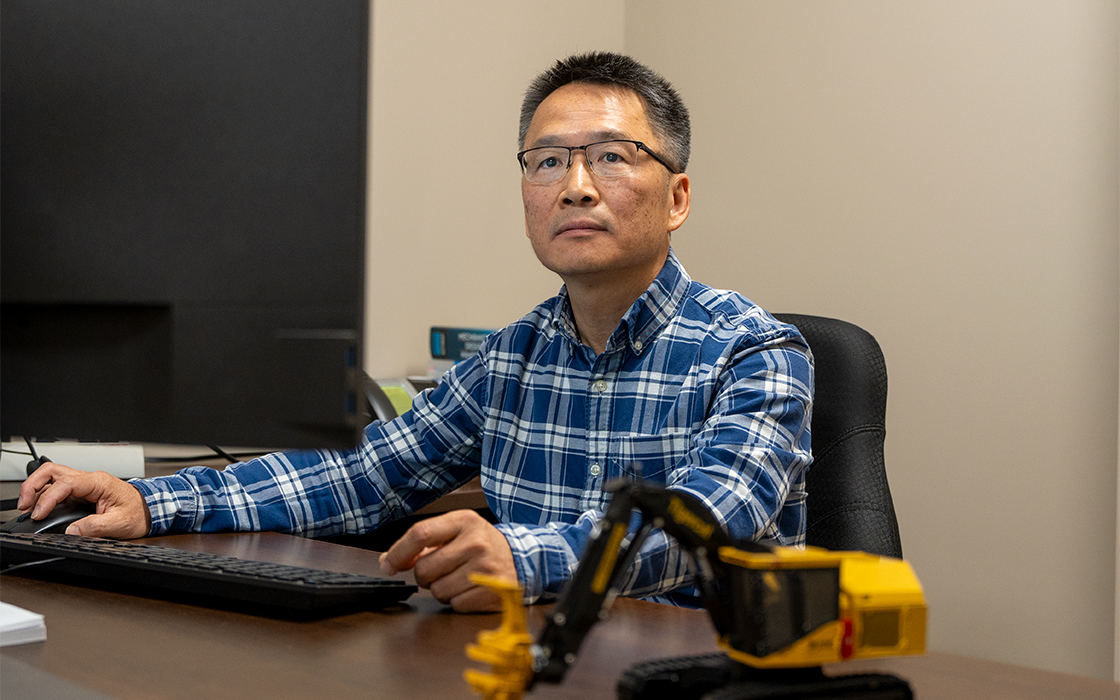

Tigercat has a reputation in the marketplace for producing high-quality, durable, and well-designed products. Every employee who works on a machine from the research and development stage through to the aftersale support plays an important role in the process. This series will look at different roles within Tigercat, introducing the team members who perform specialized tasks. READ MORE

Tigercat has a reputation in the marketplace for producing high-quality, durable, and well-designed products. Every employee who works on a machine from the research and development stage through to the aftersale support plays an important role in the process. This series will look at different roles within Tigercat, introducing the team members who perform specialized tasks. READ MORE

Tigercat has a reputation in the marketplace for producing high-quality, durable, and well-designed products. Every employee who works on a machine from the research and development stage through to the aftersale support plays an important role in the process. This series will look at different roles within Tigercat, introducing the team members who perform specialized tasks. READ MORE

Subscribe

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |