Resources

Street Trenchers Make Inroads on Long Island

20 November 2018

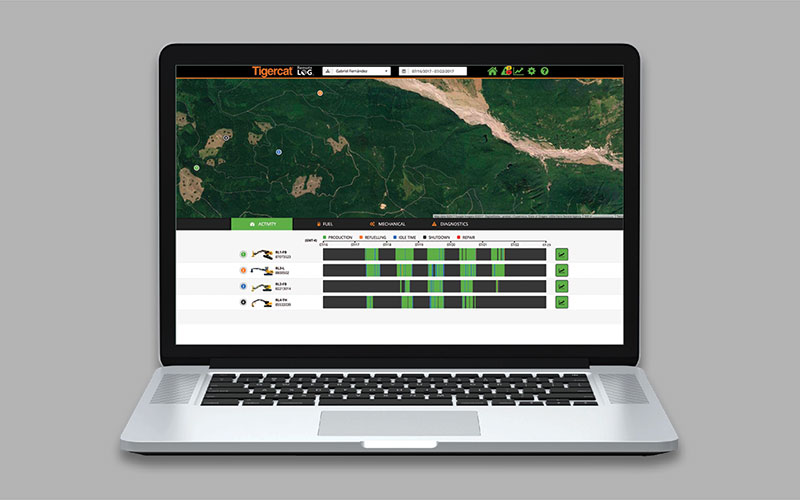

The Tigercat T726G trencher is tearing it up on the roads of Long Island, New York. BTB talks to a couple of customers to get their impressions of the machines and street trencher dealer, StreetWorksUS based in Durham, Connecticut.

Street Trenchers in Long Island

15 August 2018

Watch Tigercat street trenchers opening up the mean streets of Long Island with both asphalt and reinforced concrete road surfaces and strata. Find out from our customers why the T726G trencher is an asset and a key piece of equipment in utility infrastructure installation applications.