Resources

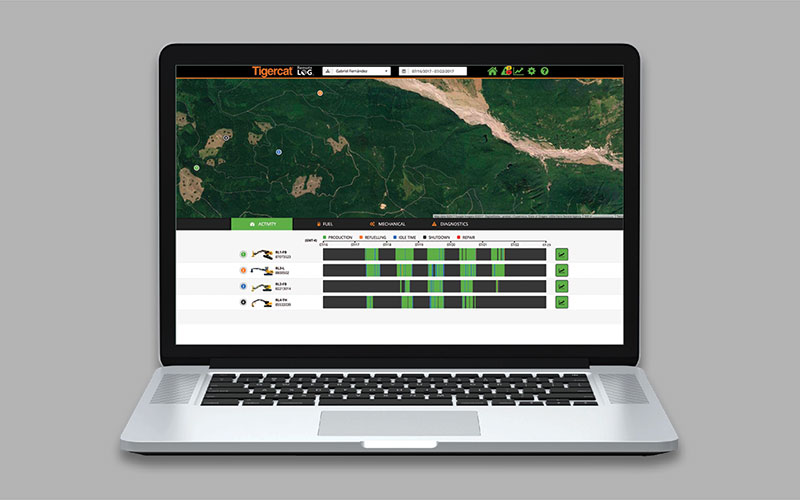

The Full Package

13 July 2020

BTB catches up with Sunshine Logging Ltd. after the Kaslo, British Columbia based company purchased two Tigercat 850 processors, each equipped with the Tigercat 568 processing head.

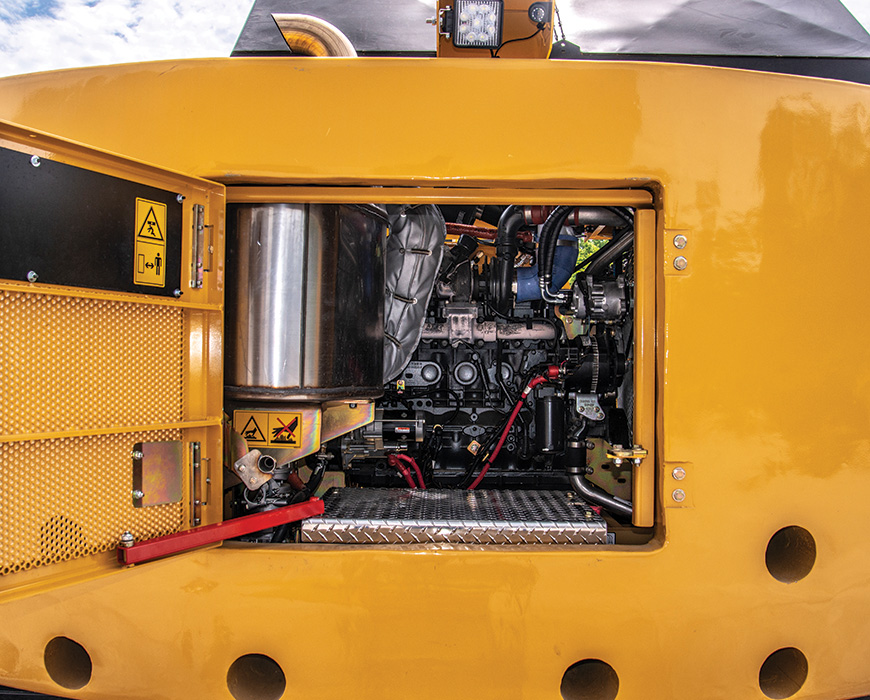

850 Processor Walk-around

02 November 2020

Tigercat product manager, Aaron Wilkes takes us on a walk-around of the 850 processor. Learn about the key features that set the Tigercat 850 roadside processor apart from excavator conversions.

Harvesting Head Brochure

04 May 2022

Download the Tigercat harvesting head brochure. Compare models to match a head to your applications. Discover more about Tigercat's end-to-end harvesting and processing solutions.