Resources

Cut-to-Length In Quebec

07 May 2022

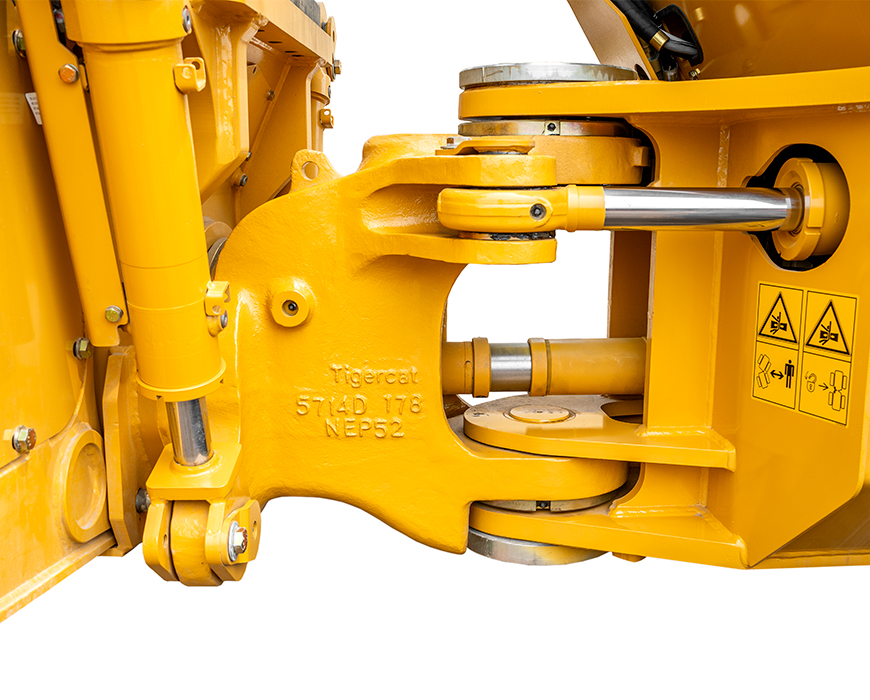

We visited contractor Antonin Beauséjour along with operators Cedric Laferrière and Kevin Correnti to get their thoughts on the two new Tigercat H822E/570 harvester packages purchased in late 2021.

Fennell Forestry's Frontrunner

30 April 2018

Samantha Paul continues with her second installment in the new Between the Branches Feature, Women in Logging. Samantha profiles Wendy Fennell, CEO of Fennell Forestry, headquartered in Mount Gambier, South Australia.

Traction Aids and Tire Maintenance

24 January 2023

Watch this Traction Aids and Tire Maintenance video to learn more about the proper selection and use of traction aids, as well as best practices for maintaining forestry tires.

1085C Forwarder in Quebec

09 June 2017

Watch a 1085C forwarder in action. Owned to Jocelyn Gagne of MULTI 2P Inc. and operating near Chibougamau, Quebec.

Forwarder Walk-around

17 November 2021

Forwarder product manager, Rob Archibald takes us on a walk-around of the three forwarder models, covering the 1055C, 1075C, and 1085C. Watch to learn about the key benefits of owning a Tigercat forwarder.