Resources

Check your Snubber

01 December 2014

Learn how to properly maintain and adjust grapple skidder snubbers and why it is so important to do so.

Traction Aids and Tire Maintenance

24 January 2023

Watch this Traction Aids and Tire Maintenance video to learn more about the proper selection and use of traction aids, as well as best practices for maintaining forestry tires.

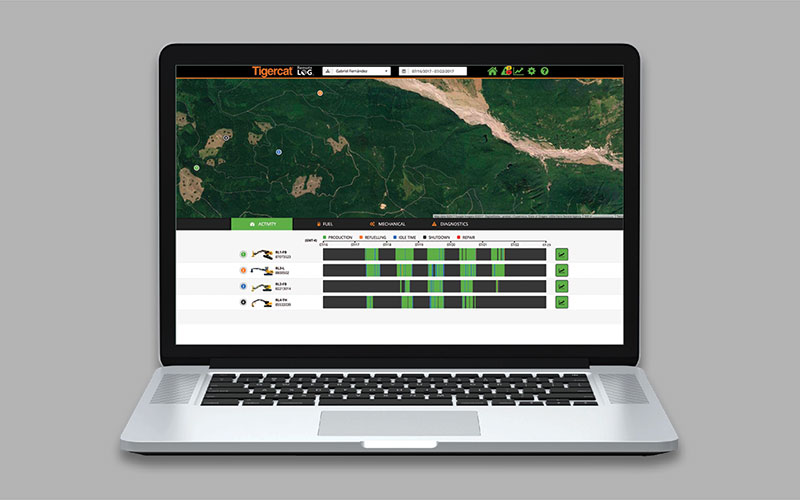

H-Series Skidders Walk-around

07 August 2020

Skidder product manager, Jeremy Piercy takes us through the H-series skidders. Get an insider's perspective on the improvements and the logic behind the design decisions. Tigercat builds a full line of four-wheel and six-wheel bogie skidders.

H-Series Seat and Controls

23 November 2020

Skidder product manager, Jeremy Piercy covers the H-series joystick controls and the new 220° Turnaround® seat system. The increased rotation envelope, along with full machine controls that rotate with the seat, offer improved ergonomics and expanded possibilities for H-series skidder operators.