Resources

Tigercat Seat Adjustments

21 April 2025

With the exception of forwarders and harvesters, all current 2025 Tigercat models are equipped with a common operator’s seat. In this video, to help you get the best performance from the seat, we are going to take you through the adjustments and point out some differences specific to certain machine models.

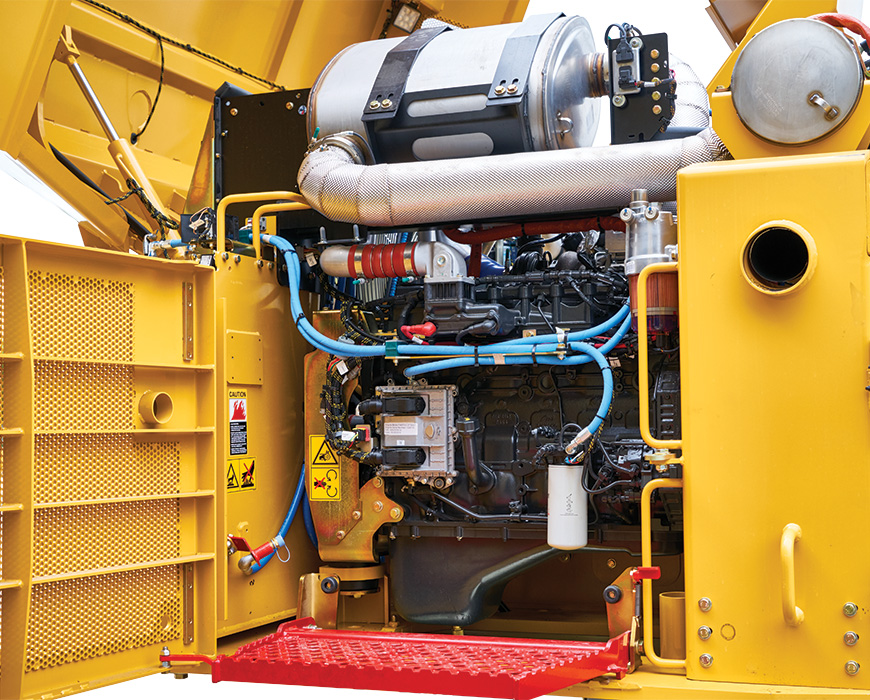

C640E Clambunk with S860C Shovel Logger

11 August 2016

Tigercat C640E clambunk skidder working with an S860C shovel logger on log mats in a lowland logging operation. Massive drags delivered to a 250D loader at roadside.

Clambunk Skidder and Shovel Logger

22 February 2016

A Tigercat S860C shovel logger loading a C640 clambunk skidder in a Georgia lowland logging application.

5195 Directional Felling Saw Brochure

28 March 2021

Download the brochure. Discover how the 5195 can work or you in large timber and steep slopes.