Resources

Steep Slope Logging in Chile

25 November 2017

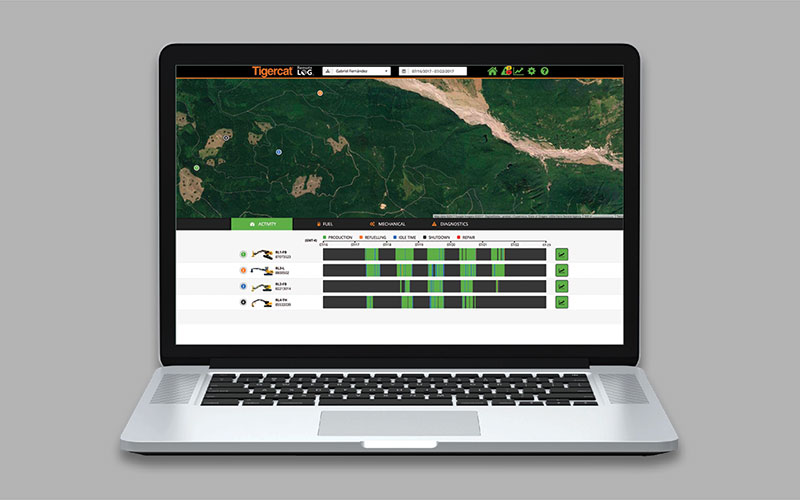

An update on the processes, technologies and advancements at work in Chile's challenging steep slope and cable assist logging operations.

Track to Success

31 July 2016

Track replacement is one of the largest operating expenses for any tracked machine.

Shovel Logger Training in Chile

18 March 2024

Tigercat talks to Francisco Sandoval, a shovel logger instructor from Chile, to learn more about a novel logging training program and how Tigercat machines have become a valuable learning tool for future Chilean machine operators.

Krume Logging Cable Assist Trial

15 June 2015

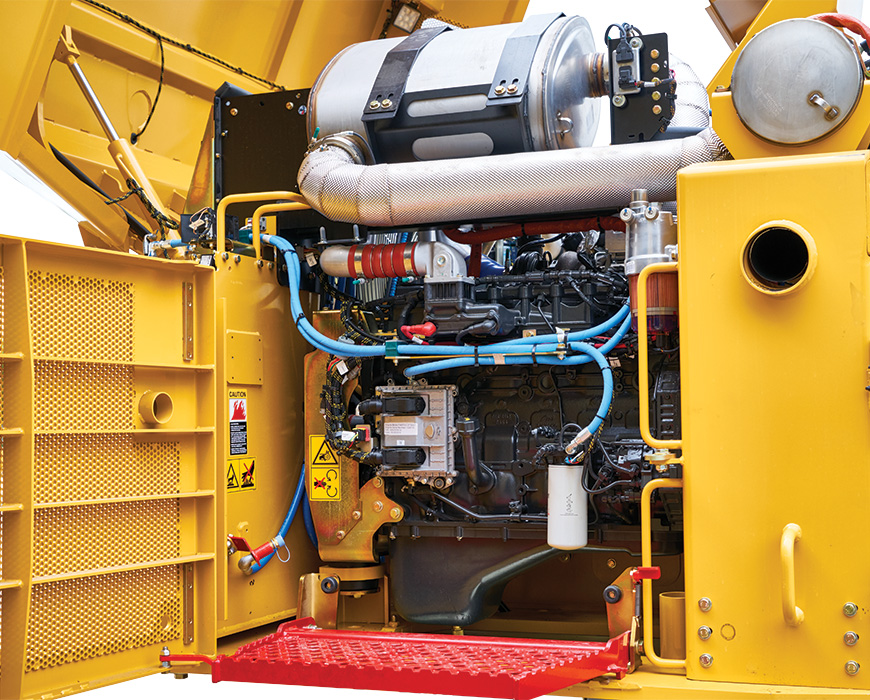

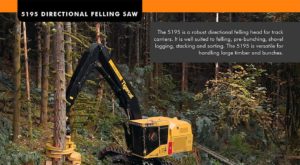

Krume Logging tests its fully automated cable assist logging system in 2015. The Tigercat LS855C shovel logger equipped with the 5195 directional felling head is felling and bunching on a 60% slope that steepens to 80% near the bottom.

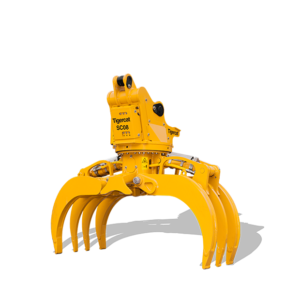

LS855D with 5195 Directional Felling Saw

08 November 2016

The Tigercat LS855D shovel logger equipped with the the 5195 directional felling saw. The machine is felling and pre-bunching oversize timber in a steep slope application with rocks, benches, drop-offs and massive old growth stumps.

5195 Directional Felling Saw Brochure

28 March 2021

Download the brochure. Discover how the 5195 can work or you in large timber and steep slopes.