Resources

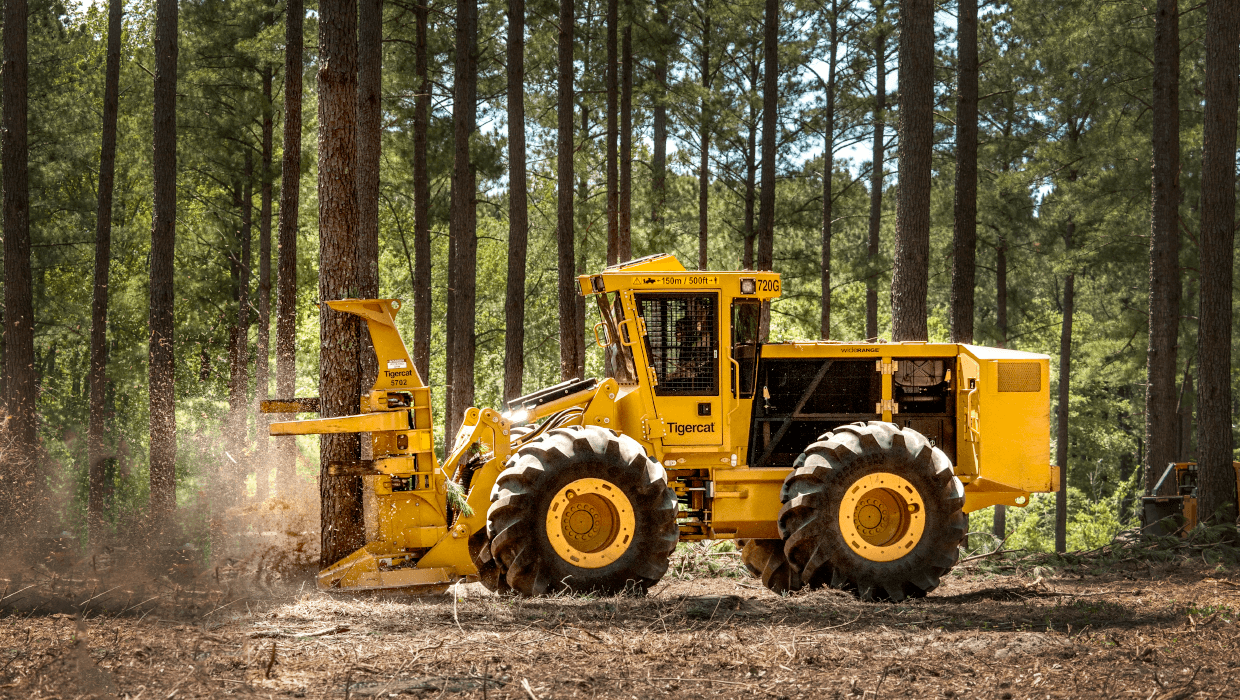

A Seasoned Professional

01 November 2023

Maryland-based contractor, FD Eure Inc., is owned by Franklin Eure. His 83-year-old father, Frank, is on the job every day operating a Tigercat feller buncher. BTB visits to learn about his very long professional life and what keeps him motivated to crank up his machine before dawn each morning.

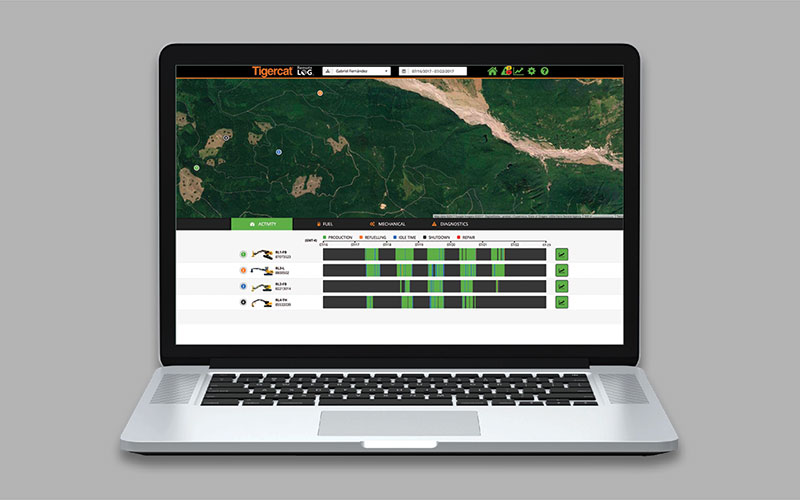

Mechanized Teak Harvesting

10 November 2020

José Carlos Rocha Filho, marketing and commercial manager at Latin Equipment Norte, explores the mechanization of teak plantation harvesting in southeastern Mexico.

Fire Safety for Feller Bunchers and Mulchers

07 January 2015

Compared to other mobile industrial machines, equipment used in forestry has an above average risk of being damaged or destroyed by fire. Take the right steps to minimize the risk of fire. Learn more about best practices.

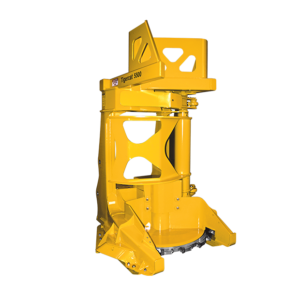

Felling Heads Brochure

16 September 2021

Download the Tigercat felling head brochure. Compare models to match a felling head to your application. Discover the productivity and efficiency benefits.