Resources

Felling Heads Brochure

16 September 2021

Download the Tigercat felling head brochure. Compare models to match a felling head to your application. Discover the productivity and efficiency benefits.

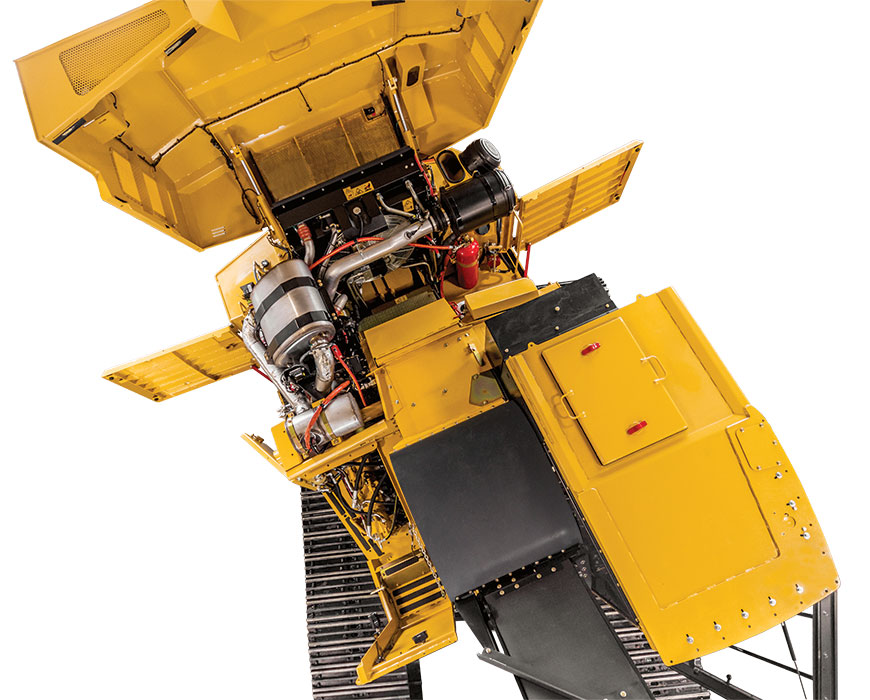

5185 Fixed Felling Saw Brochure

17 August 2020

Download the brochure. Discover how the 5185 can work or you in large and high value timber applications.